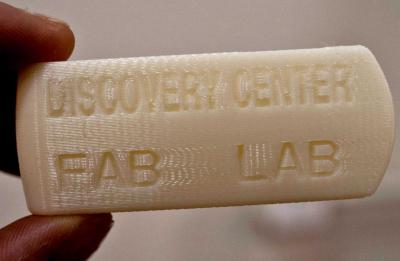

For nearly a decade, the Discovery Center Fab Lab at UW-Stout has been a cutting-edge center to help bring innovative ideas to life.

Now in its 10th year of operations, the Fab Lab — a design and digital fabrication laboratory — still is the only such facility available to all students at a Wisconsin university. And, adhering to the Wisconsin Idea, it has grown to help meet the needs of residents across the state.

Since 2016 the Fab Lab has hosted WiFab, a workshop for teachers in Wisconsin school districts. WiFab West was held June 14-16 on campus, with 15 teachers from nine school districts, from Drummond to Milwaukee, from Bowler to Elmwood.

WiFab East, hosted by UW-Stout, will be held Tuesday to Thursday, July 19-21, at Fox Valley Technical College in Appleton.

The workshops help train teachers who are new to fab lab technology, including many whose schools received fab lab funding from the Wisconsin Economic Development Corp. Teachers take the lessons learned at WiFab, such as how to use a laser engraver or 3D printer, back to their colleagues and to their district’s students.

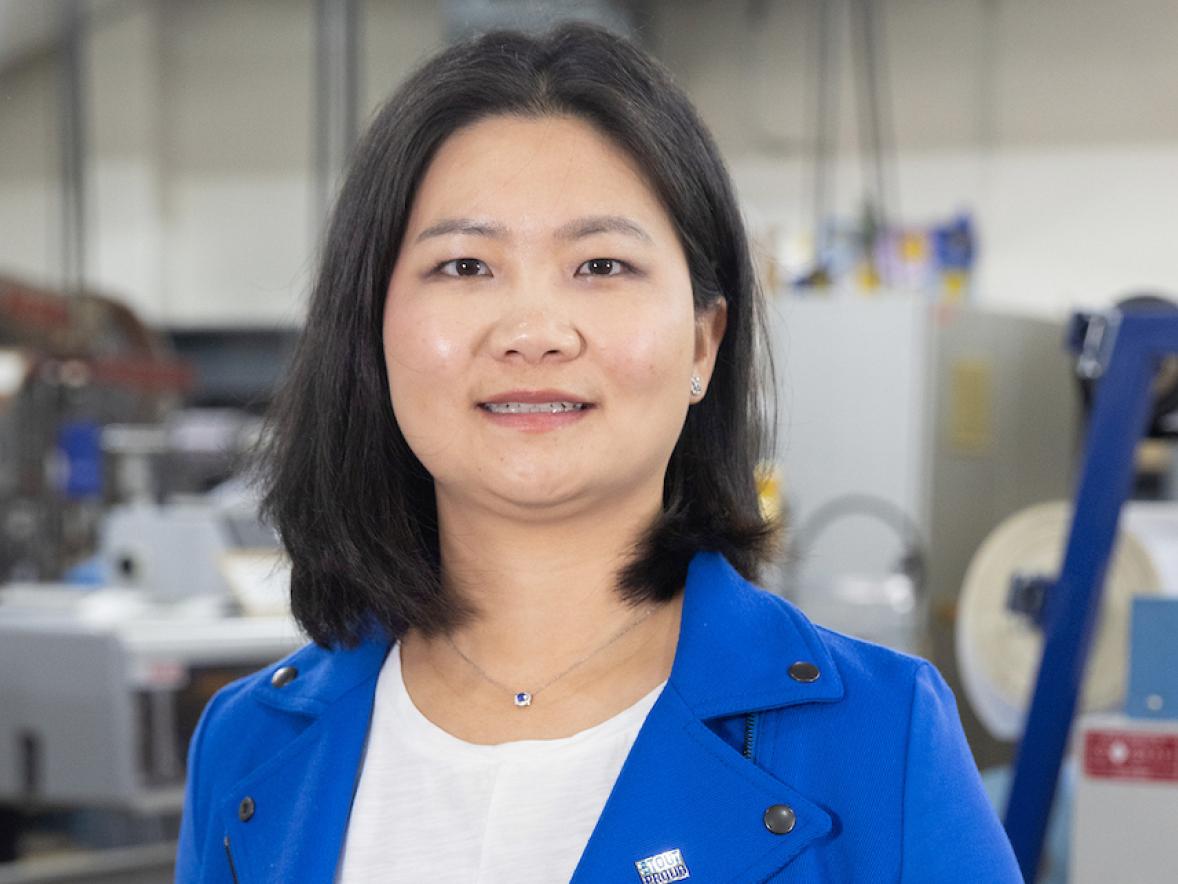

Mike Cropp, UW-Stout Fab Lab manager, teaches the retreats with Steve Meyer, manager of STEM education and development at Fox Valley Technical College; and Laurence Charlier, fab lab director at Northwestern High School in Maple, a technology and engineering teacher and a UW-Stout alum.

WEDC has awarded 100 fab lab grants to school districts since 2016.

“If we can have an impact on individuals to think creatively and make things that are meaningful to them at an early age, it really empowers education and is meaningful to their lives,” said Randy Hulke, Discovery Center director who recently retired.

For the school districts that received WEDC fab lab grants, UW-Stout also provides a WEDC-funded WiFab Cooperative to support lab layout, equipment selection, curriculum development and more, Hulke said.

School district outreach is one of three areas UW-Stout’s Fab Lab provides for engagement. Also:

- The lab, in the Vocational Rehabilitation Building, is open to the public for entrepreneurs and others hoping to develop an idea or product. Users can apply online to use the lab.

- The lab is open to UW-Stout students from every major at no cost. Up to 1,000 students a year from every major have used it, Hulke said.

Since it opened in 2013, the lab has added a second laser engraver, a second minimill and increased its 3D printers from three to six, as well as adding a plasma cutter for metal. Students, faculty and staff reserve time to use the equipment.

“These equipment enhancements help accommodate the number of users and the type of material they want to work with,” Hulke said.

The Fab Lab, like its mission, is hoping to innovate how its technology can be used. An initiative being developed is working with clients of the Discovery Center’s Manufacturing Outreach Center.

“How can we use these tools to help automate a job in some way or make a tool to make it easier?” Cropp said. “It’s simple automation. We can help solve simple problems using technology as the starting point.”

UW-Stout’s Fab Lab was founded with the assistance of a multiyear $520,000 Growth Agenda award from the UW System. It features digital fabrication machines that are programmed through computer software.

The Fab Lab provides access to a variety of tools, including computer-aided design and desktop manufacturing technologies, to help bring ideas to life. The open Fab Lab environment removes barriers, such as access to equipment and technology, while serving as an incubator for applied research, innovation, job creation and economic development.

The WiFab workshops are coordinated by UW-Stout’s Professional Education Programs and Services.

###