At University of Wisconsin-Stout, Wisconsin’s Polytechnic University, all of the academic programs have an experiential learning component.

For students from seven of those programs, the applied learning and collaborative experiences will be even more robust for years to come with the completion of a $3 million lab and facilities renovation project.

The centerpiece of the project is a 3-in-1 Makers Laboratory on the third floor of Fryklund Hall, which houses the Robert F. Cervenka School of Engineering. Students from the fashion and retail program and all six engineering and technology programs now have a flexible space when needed.

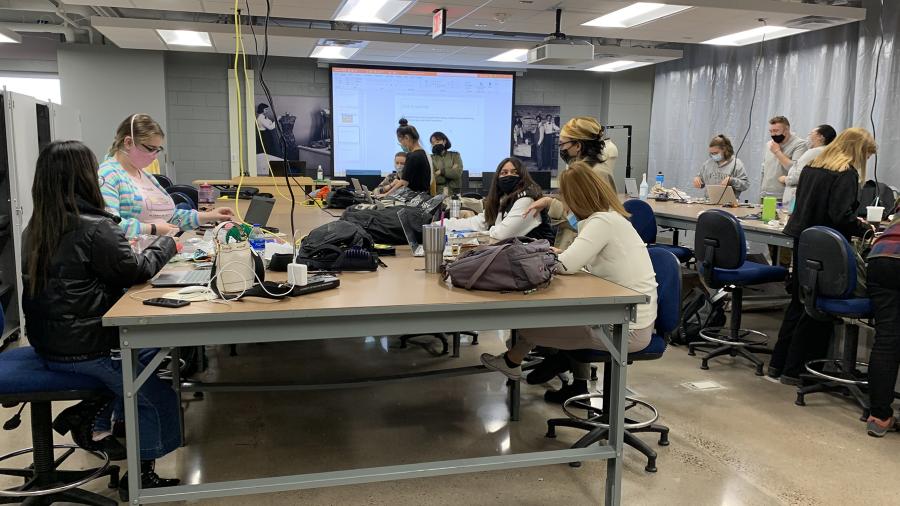

The space, with movable dividers, has a common central teaching area and labs on each side.

Fashion and retail students have an updated garment construction lab, said Belinda Banike, the program director. Engineering and technology students have a new space for projects, including for storage and power tools, said Professor Tom Lacksonen, engineering and technology department chair.

With large work tables and a central audiovisual screen, the center flex space is designed to help students collaborate on in-class and special hands-on projects. Also, it promotes collaborative projects between the majors, said Chris Bendel, associate dean of the College of Science, Technology, Engineering, Mathematics and Management.

Other academic majors also can benefit from the maker space, Bendel said.

He said it’s a “flexible, multidisciplinary setting” where the “tables and furnishings are appropriate for making things, and there is some ready access to tools and equipment.”

One of the goals of UW-Stout’s FOCUS2030 strategic plan is to advance the university’s polytechnic reputation by “providing students access to cutting edge technology, innovative programs and collaborative partnerships that support the development of interdisciplinary knowledge and skills.”

Glendali Rodriguez, provost and vice chancellor for Academic Affairs, said the lab renovation helps address that goal.

“At UW-Stout, we have three times as many labs as classrooms. That statistic is significant — it reflects how our buildings and programs intentionally facilitate learning through spaces that allow applied experiences,” Rodriguez said.

“The renovation of this key space is just one example of our strategic approach to creating environments that foster hands-on, cross-disciplinary learning. We are excited about the flexibility it affords and appreciative for the state’s support in alignment with our mission as a polytechnic university,” she said.

Funding for the project was approved in October 2020 by the State Building Commission.

The project was completed by UW-Stout’s Facilities Management.

Other improvements

Near the Makers Laboratory is a new computer-aided design — CAD — lab and an expanded and remodeled conference room, both part of the project.

Finally, funding was used to create a new materials testing lab for fashion and retail in the adjoining Communication Technologies Building. The old testing lab was in Heritage Hall.

The new testing lab, where students analyze the properties of materials that go into clothing, is about three times larger. Students can “work together much more easily,” Banike said, including in groups of 10 to 15, and the equipment is more accessible than previously for group work.

Near the materials testing lab is new storage and display for the program’s garment collection.

With the changes, all fashion and retail labs are now in Fryklund and Communication Technologies, which are connected via an indoor walkway. Previously, students had about a two-block walk to Heritage.

Most of the renovated spaces have enlarged historic photos of labs at UW-Stout.

The project additionally helps address a proposed complete renovation of Heritage Hall, home to the College of Education, Hospitality, Health and Human Sciences.

Fryklund Hall, named after former school President Verne C. Fryklund, opened in 1962.

###